Product Information

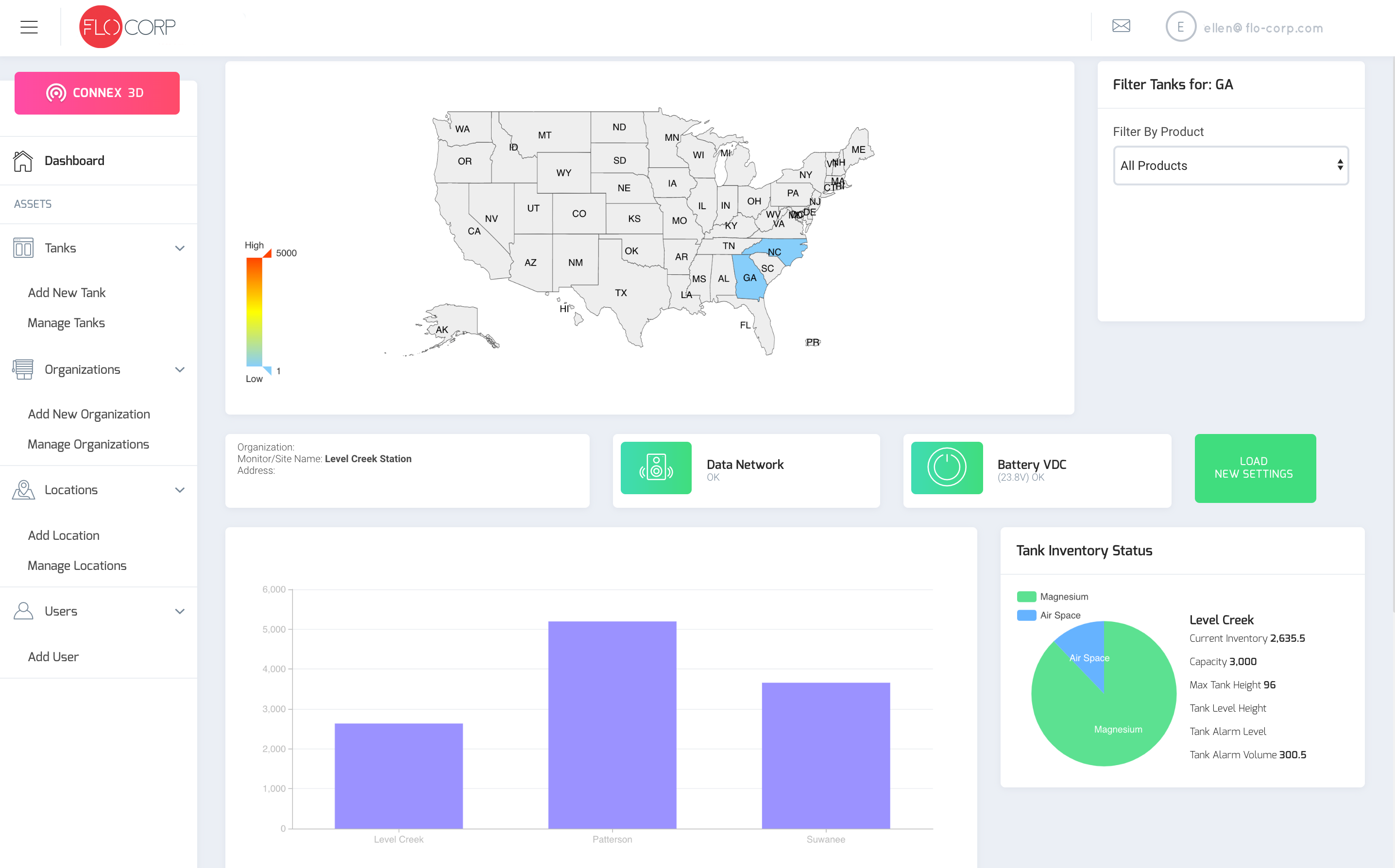

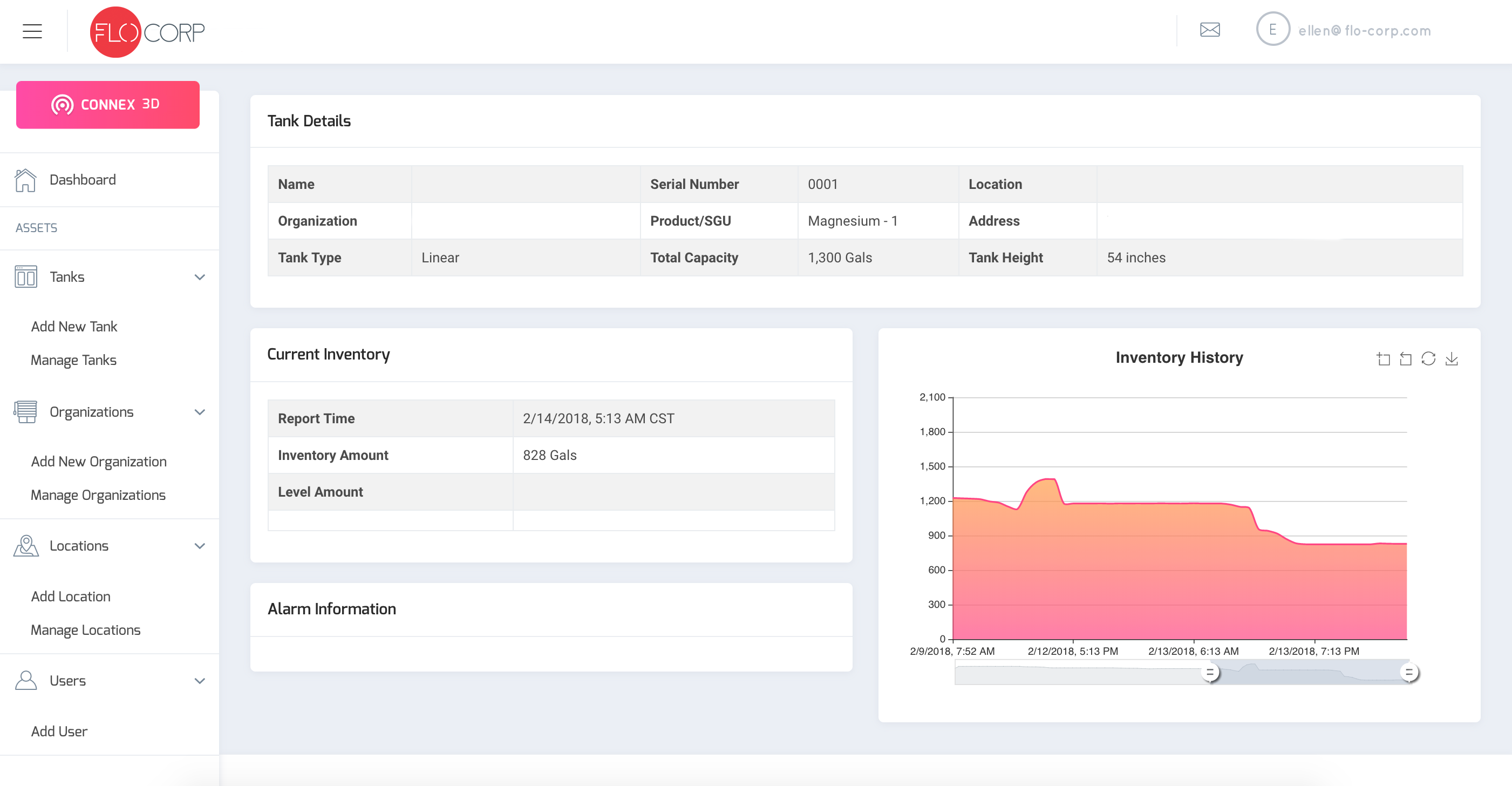

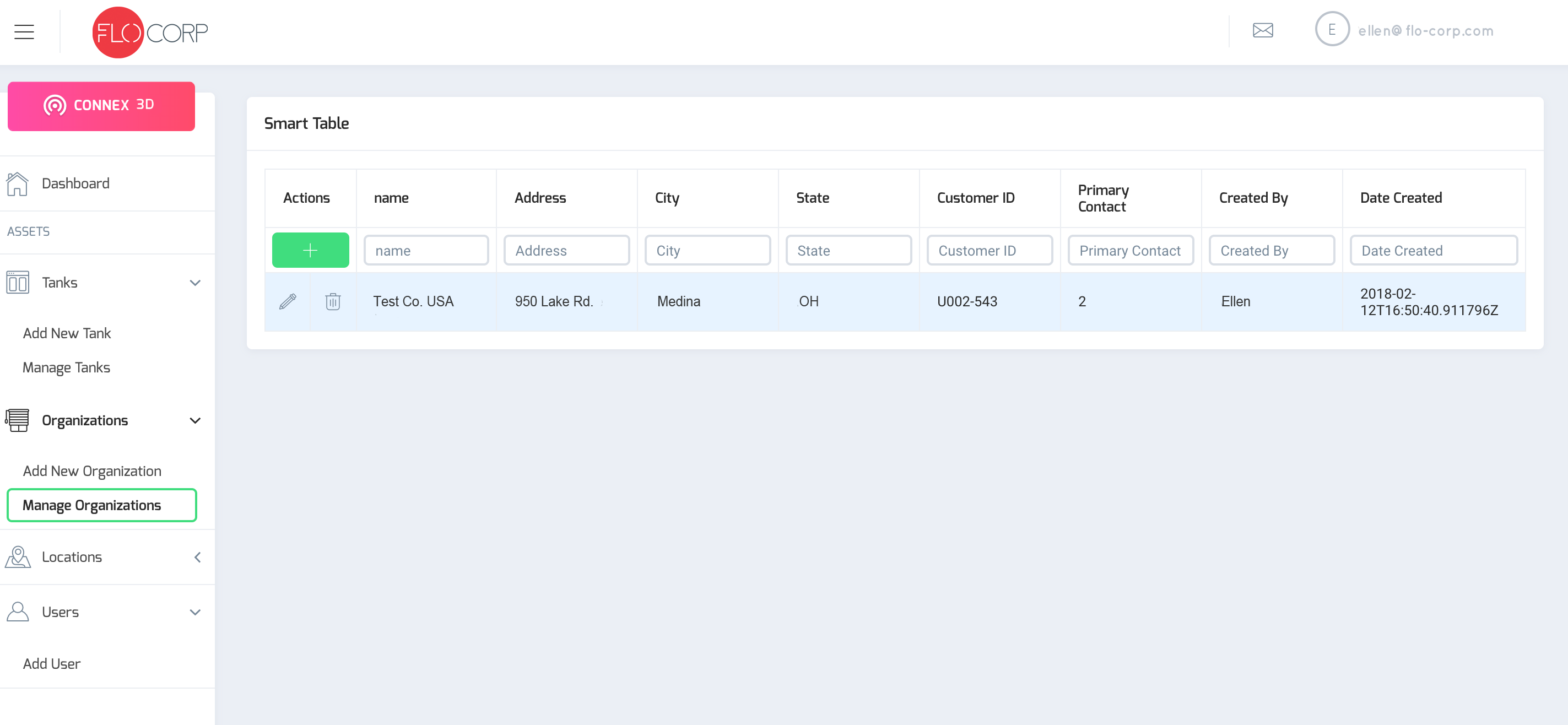

FLO-CORP introduces the patent pending CONNEX 3D™ Wireless Cellular Process Monitor. The industry’s first process cellular monitor that communicates to field and host devices via RS485 and transmit wirelessly through cellular data transmission to the CONNEX 3D™ Online Portal, a cloud based server. The CONNEX 3D™ Online Portal allows users to monitor multiple tanks in one place. Receive alarms when tank levels are too high or too low, check battery levels, network status and much more.

Part Number: CD3D-CELL

Replaces Part Number: G1-1-GP-NN

FLO-CORP introduces the patent pending CONNEX 3D™ Cellular Modem. The industry’s first process cellular monitor that communicates to field and host devices via RS485 and transmit wirelessly through cellular data transmission to cloud based server. The server data can be displayed on any PC, Smartphone, Tablet, any device with a Web Browser. From point A to point B, the CONNEX 3D provides the user flexibility to configure any standard analog input or RS485 Modbus input using a laptop or PC USB direct programming setup tool for monitoring setup and diagnostic interface. The CONNEX 3D Cellular Modem offers the added benefit of connecting multiple field devices into one monitor for signal data plan networking measuring multiple field devices. The added cost savings of single data plan monitoring can now be a reality for multiple device applications such as tank farms, process flow monitoring, remote pump stations monitoring and more. Data gathering has never been easier. The CONNEX 3D cellular monitor includes a built-in data logger with up to 32,000 samples of data stored for field retrieval and/or cellular transmission in one upload. Now, even when cellular connectivity is lost, your measuring data isn’t. The network capabilities are cutting edge, featuring compatibility with LPWAN networks, cellular networks, point-to-point networks, and wired networks. The CONNEX 3D Display, bright 6 digit LED field or panel display is compatible with the new CONNEX 3D modem so now the field signal can also be displayed in the field for plant operations and easy prompting of measurement conditions. FLO-CORP’s cost-saving hardware and software design provides process control and monitoring, data gathering, data reporting, alarm alerting via SMS and email, alarm historian and more.

| Product Type | Wireless |

|---|---|

| Part Number | CD3D-CELL |

| Replaces Part Number | G1-1-GP-NN |

Related products

PDFlo™ PDSG1 Positive Displacement Spur Gear Flow Meter

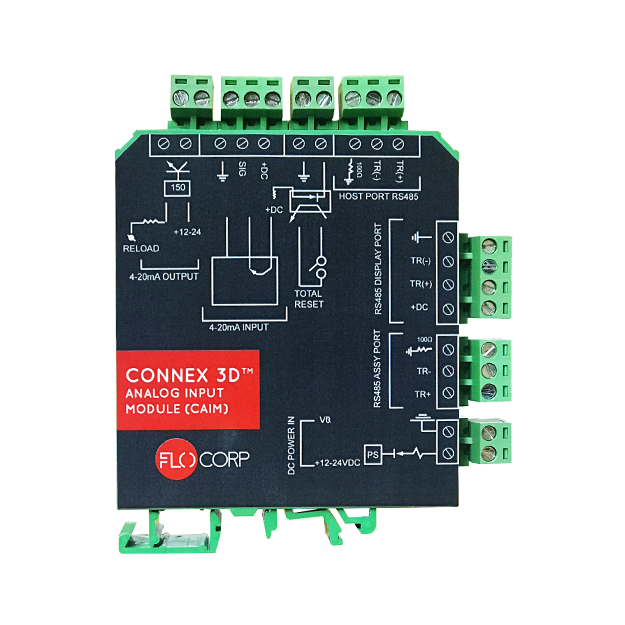

Analog Input Module (CAIM): CONNEX COMPATIBLE

The Analog Input/Output Module for the CONNEX 3D™ Flexible Meter provides the input from a variety of standard analog inputs such as flow, level, pressure, temperature, pH and analytical inputs to standard field instruments and measurements.

MEMFlo™ MFVC Volumetric VA Flow Meter (DISCONTINUED)

Driver License Terms The software you can download from this web site ("the Software") is provided by Future Technology Devices International Limited ("FTDI") subject to the license terms set out at http://www.ftdichip.com/FTDriverLicenceTerms.htm ("the License Terms"). You must read the License Terms before downloading the Software. By installing or using the Software you agree to the License Terms. If you do not agree to the License Terms then do not download or use the Software. Without prejudice to the License Terms, here is a summary of some of the key terms of the License Terms (and in the event of any conflict between this summary and the License Terms then the text of the License Terms will prevail). The license only allows use of the Software with, and the Software will only work with Genuine FTDI Components (as defined in the License Terms). Use of the Software as a driver for a component that is not a Genuine FTDI Component MAY IRRETRIEVABLY DAMAGE THAT COMPONENT. It is your responsibility to make sure that all chips you use the Software as a driver for are Genuine FTDI Components. If in doubt then contact FTDI. The Software is provided "as is''. There are no warranties (or similar) in relation to the quality of the Software. There are exclusions of FTDI liability for certain types of loss such as: special loss or damage; incidental loss or damage; indirect or consequential loss or damage; loss of income; loss of business; loss of profits; loss of revenue; loss of contracts; business interruption; loss of the use of money or anticipated savings; loss of information; loss of opportunity; loss of goodwill or reputation; and/or loss of, damage to or corruption of data. There is a monetary cap on FTDI's liability. If a custom vendor ID and/or product ID or description string are used, it is the responsibility of the product manufacturer to maintain any changes and subsequent WHQL re-certification as a result of making these changes.